Upon receipt and in advance of acceptance, each container or grouping of containers of materials must be examined visually for right labeling (which include correlation involving the title employed by the supplier and the in-dwelling identify, if these are typically diverse), container damage, broken seals and evidence of tampering or contamination.

This device is suitable for the synthesis of an array of APIs spanning a variety of therapy parts. This device comprises 3 generation blocks and it has an yearly generation ability of a hundred and eighty.00 MT. At this device, we develop APIs throughout a broad spectrum of therapeutic classes. Barwala

Each company really should set up, doc, and implement an effective method for handling high-quality that consists of the active participation of administration and proper manufacturing staff.

Computerized programs should have ample controls to forestall unauthorized access or variations to facts. There needs to be controls to circumvent omissions in facts (e.

In-course of action controls as well as their acceptance standards must be described depending on the knowledge obtained in the course of the developmental phase or from historical info.

The controls Utilized in the manufacture of APIs for use in medical trials need to be according to the phase of enhancement in the drug solution incorporating the API. Procedure and test methods ought to be adaptable to offer for changes as familiarity with the procedure increases and medical screening of the drug merchandise progresses from pre-medical stages through scientific levels.

Expiry Date (or Expiration Day): The date placed on the container/labels of the API designating the time throughout which the API is expected to remain in just recognized shelf everyday living technical specs if saved underneath described circumstances and and then it really should not be used.

Raw materials for intermediate and API manufacturing need to be weighed or measured underneath acceptable problems that do not have an impact on their suitability for use. Weighing and measuring gadgets really should be of acceptable accuracy for your supposed use.

The sterilization and aseptic processing of sterile APIs are usually not coated by this direction, but needs to be done in accordance with GMP guidances for drug (medicinal) products as outlined by area authorities.

Relative to the topic in hand, CMC teams can be required to carry out method validation before than normal. The CMC group can not skip measures but rather should arrive at levels of readiness at a level speedier than check here regular.

In the majority of environments, there will be considered a closing evaluation of any adjustments applied within the plant throughout the registration batches, observe-up revisions arising from your put up-action overview, and closing protection changes along with the completely outlined processing parameters. These final evaluations are known as “engineering batches."

The corporation explained it was conducting assessments to determine the ingredients that were unexpectedly present in these products.

Deviations from authorised specifications of calibration on vital devices needs to be investigated to find out if these might have experienced an effect on the caliber of the intermediate(s) or API(s) manufactured employing this machines Because the last thriving calibration.

Quality expectations to the CMC part keep on being equally as stringent in such plans. For that reason, enhancement time may be handed more than and prioritized toward method Management to guarantee protection and high quality. There may well most likely be considered a lowered variety of plant batches of each and every phase because of the commercial approach as might be ideally meant to acquire expertise and comfort.

Ben Savage Then & Now!

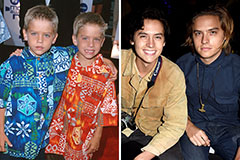

Ben Savage Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!